After decades of decline, U.S. manufacturing is making a comeback. But this isn’t the manufacturing revival of the past—this is manufacturing reinvented for the future. In 2025, factories are no longer just about assembly lines and manual labor. They are intelligent, data-driven ecosystems powered by robotics, AI, sensors, and real-time analytics. The resurgence of American industry is happening—but it’s happening smarter.

At the heart of this transformation is a profound shift in how value is created. Today’s manufacturers aren’t competing on cost alone; they’re competing on precision, speed, innovation, and flexibility. Gone are the days when the cheapest labor dictated the direction of supply chains. The new competitive edge comes from automated systems, advanced materials, clean energy, and digitally integrated production. The companies leading the charge are using smart manufacturing to bring jobs back to the U.S., reduce reliance on fragile overseas supply chains, and produce better products faster.

Much of this comeback is fueled by necessity. The COVID-19 pandemic and subsequent global disruptions exposed the vulnerabilities of a hyper-globalized supply model. When ports shut down, container ships stalled, and key components like semiconductors became scarce, businesses and governments alike began rethinking the risk of offshore dependence. Add to that rising geopolitical tensions and transportation costs, and reshoring production has moved from patriotic ambition to strategic necessity.

Federal policy is also playing a major role. Landmark legislation like the CHIPS and Science Act and the Inflation Reduction Act have committed hundreds of billions of dollars to bolster domestic manufacturing. These investments are being used to build semiconductor fabs, battery plants, clean energy infrastructure, and advanced manufacturing hubs in states like Arizona, Ohio, Michigan, and Texas. Incentives such as tax credits, R&D grants, and workforce development funding are drawing manufacturers back to American soil in ways we haven’t seen in decades.

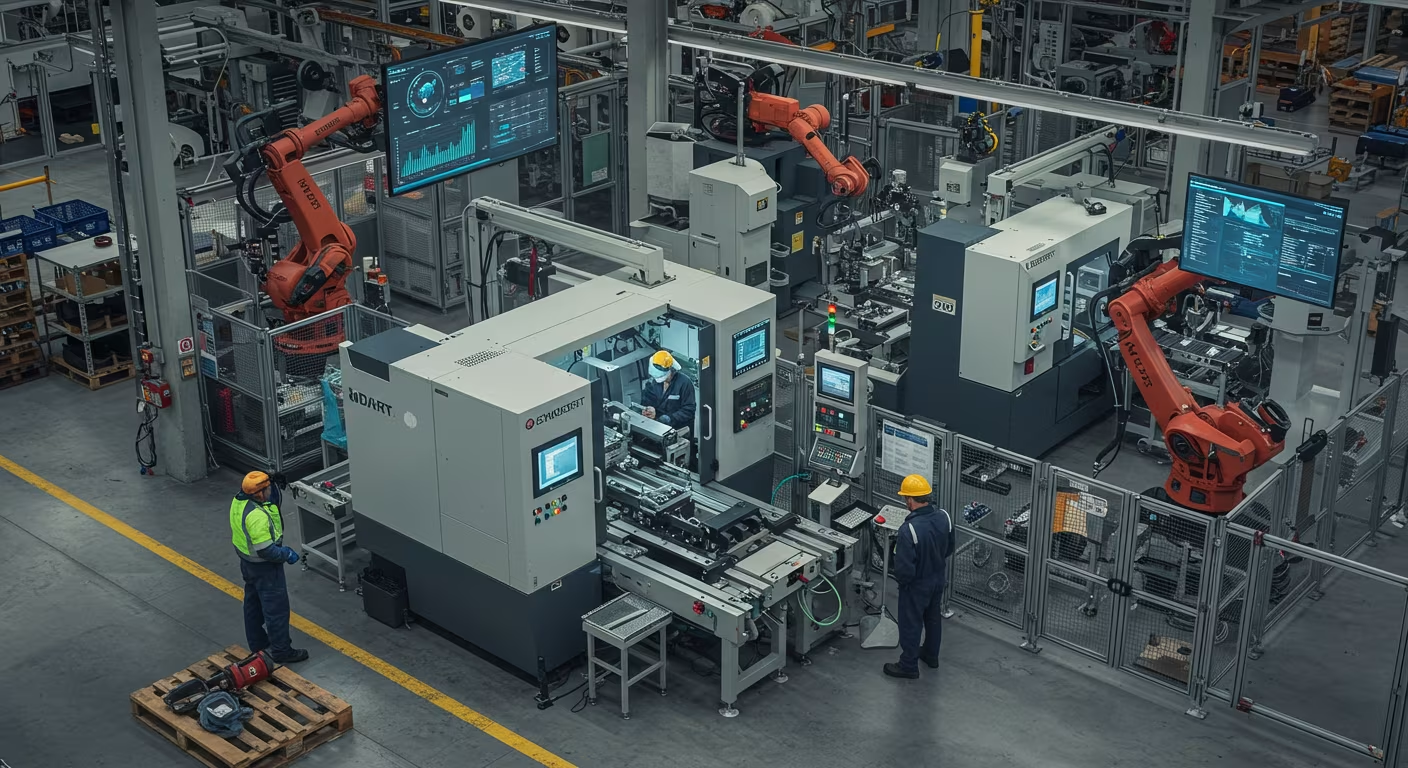

But the biggest difference this time around is that the factories coming online in 2025 look nothing like the ones that shuttered in the 1990s. Today’s facilities are sleek, autonomous, and connected. Think robotic arms performing intricate tasks with sub-millimeter accuracy, machine-learning systems adjusting production based on real-time sensor feedback, and cloud-based control rooms where engineers monitor operations from across the country.

One standout example is Intel’s massive new semiconductor facility in Ohio, billed as one of the most advanced chip plants in the world. Designed from the ground up with automation and AI in mind, the factory will not only produce next-generation semiconductors but also serve as a blueprint for what modern U.S. manufacturing can achieve. Similarly, Tesla’s Gigafactory in Texas uses a combination of robotics, vertical integration, and energy efficiency to produce vehicles and batteries at a scale and speed unmatched by traditional auto plants.

The rise of Industry 4.0—a term that encompasses smart manufacturing, IoT, and cyber-physical systems—is transforming how products are made. Factories now operate with minimal human oversight, using digital twins to simulate entire production lines before a single machine is activated. Predictive maintenance systems monitor machinery health and prevent downtime. Sensors on the shop floor provide real-time visibility into quality, energy use, and safety metrics. These technologies not only improve efficiency but also reduce waste, energy consumption, and error rates.

Importantly, this smarter model of manufacturing doesn’t mean fewer jobs—it means different jobs. The return of U.S. manufacturing is creating a new category of employment centered around engineering, data science, AI programming, robotics maintenance, and digital operations. Today’s factory worker is more likely to carry a tablet than a wrench, and training programs are evolving rapidly to support this shift. Community colleges, universities, and private bootcamps are partnering with manufacturers to develop credentialed programs that align with modern factory needs.

Companies are also investing in upskilling existing workers. Employers like GE, Siemens, and Ford are retraining technicians to manage smart equipment, analyze data outputs, and oversee cyber-secure networks. These initiatives are helping to rebuild the middle class, particularly in regions once devastated by industrial decline. For cities like Detroit, Pittsburgh, and Youngstown, the return of high-tech manufacturing jobs is creating economic momentum not seen in generations.

This smarter manufacturing model also enables faster product iteration and greater customization. With flexible automation and real-time data, companies can shift production runs more quickly, personalize products at scale, and respond rapidly to market changes. For example, small-batch clothing brands using robotic sewing systems can launch new designs weekly. Aerospace firms can 3D print specialized parts on-demand, reducing inventory and lead times. Even consumer electronics companies are experimenting with localized assembly to meet regional demand more precisely.

Sustainability is another key factor in this new era. Smart factories are designed to minimize emissions and energy use. Many run on renewable energy, employ closed-loop water systems, and use AI to optimize power consumption. Manufacturers are increasingly held accountable not just for what they produce—but for how they produce it. The smarter the factory, the greener it can be. This aligns with growing consumer and investor pressure for climate-conscious operations, especially as ESG compliance becomes a financial necessity.

Of course, challenges remain. The capital required to build advanced manufacturing infrastructure is substantial. Smaller firms may struggle to access the technology or talent needed to fully modernize. Cybersecurity risks grow as systems become more connected, and the gap between cutting-edge and lagging facilities could widen economic inequality if not addressed. However, public-private partnerships, targeted funding, and shared innovation ecosystems are helping to close these gaps.

The return of U.S. manufacturing is not a nostalgic look backward—it’s a bold step forward. It’s not about recreating the factory jobs of the past, but about embracing a smarter, cleaner, and more agile model of production. One that leverages automation and digital intelligence not to replace humans, but to empower them. One that prioritizes resilience, quality, and national competitiveness over short-term labor arbitrage. And one that positions the United States not just as a consumer economy—but as a maker economy once again.

As the world redefines its industrial future, America is proving that manufacturing can return—on its own terms, and better than before. It won’t look like the old smokestack era. It will look like robotic precision, zero-waste assembly, and real-time analytics driving decisions from factory floors to executive dashboards. That’s not just a return. That’s a reinvention.